Managing Supply Chain Contracts: Strategy to Implementation

Supply chain contract management has evolved from an administrative function to a strategic imperative. While our previous article explored the foundational parts of supply chain CLM, this follow-up digs into implementation strategies that transform theory into practice. Organizations that implement strong contract management processes can reduce cycle times by up to 70%, reduce risk exposure, and strengthen supplier relationships across their ecosystem.

The Evolution of Supply Chain Contracts in a Post-Pandemic World

The global disruptions of recent years have changed how organizations approach supply chain contracts. The once-standard terms that governed pre-pandemic relationships have not proven enough in the face of unprecedented challenges. Contract structures have evolved to focus on adaptability and resilience over rigid efficiency.

Force Majeure Clause Incorporation

Modern supply chain agreements now commonly incorporate expanded force majeure clauses that account for previously unimaginable scenarios. Organizations are moving away from traditional just-in-time arrangements toward contracts that incentivize buffer inventories and alternative sourcing capabilities. This shift reflects a broader recognition that contract management must balance efficiency with resilience.

Supply Chain Disruption Management

Leading organizations have transformed their contracting approach by implementing tiered supplier frameworks that contractually define escalation paths during disruptions. For example, a major electronics manufacturer recently revised their standard agreements to include required disruption response plans from tier-one suppliers, ensuring synchronized responses during supply chain interruptions. These contractual innovations show how forward-thinking companies are using their agreements as strategic tools rather than mere documentation.

Building Your Supply Chain CLM Implementation Roadmap

Successful implementation of supply chain contract management requires a structured approach that addresses technology, processes, and people. Breaking the journey into manageable phases helps organizations maintain momentum while delivering incremental value.

Phase 1: Assessment and Goal-Setting

Begin with a comprehensive evaluation of your current contract management practices. This assessment should examine how contracts are created, executed, tracked, and renewed across your supply chain operations. Identify pain points, compliance vulnerabilities, and opportunities for improvement.

For example, many organizations discover that over 30% of their supply agreements have outdated terms or miss critical compliance clauses.Establishing clear, measurable goals is critical for successful implementation.

Focus on metrics that align with broader business goals, such as:

- Reducing contract cycle time from drafting to execution

- Decreasing the number of contract disputes and escalations

- Improving compliance with regulatory requirements

- Enhancing knowledge of supplier performance against contractual obligations

Without executive sponsorship and cross-functional alignment, even the most sophisticated CLM implementation will struggle to gain traction. Form a steering committee that includes representatives from procurement, legal, finance, and operations to ensure all perspectives are considered throughout the implementation journey.

Phase 2: Technology Selection and Configuration

When evaluating CLM solutions, distinguish between essential capabilities and nice-to-have features.

Core functionality for supply chain contract management includes:

- Centralized contract repository with robust search capabilities

- Automated workflow routing and approval processes

- Standardized templates with conditional clause libraries

- Milestone tracking and automated notifications

- Reporting and analytics for contract performance

Integration with existing systems represents one of the most challenging parts of CLM implementation. Your chosen solution must seamlessly connect with procurement platforms, ERP systems, and supplier management tools to eliminate data silos and provide end-to-end visibility. Focus on vendors that offer pre-built connectors for your core systems and have proven experience with similar technology ecosystems.

Data migration requires thoughtful planning, especially for organizations with thousands of legacy contracts. Develop a phased approach that begins with active high-value agreements before expanding to include historical contracts. Consider using AI-powered extraction tools to accelerate the digitization process while ensuring accuracy of key metadata.

Phase 3: Change Management and Adoption

The most sophisticated CLM technology will deliver minimal value without effective user adoption. Develop role-specific training programs that address the unique needs of different stakeholders. Contract administrators require comprehensive system training, while occasional users may need focused instruction on self-service functions and approval processes.

Communication strategies should emphasize the “what’s in it for me” for each stakeholder group. Procurement teams, highlight how CLM reduces administrative burden and accelerates cycle times. Legal departments, emphasize risk reduction and compliance benefits. Business users, focus on visibility and simplified access to contract information.

Establishing a center of excellence creates a foundation for continuous improvement and governance.

This cross-functional team should:

- Maintain contract templates and clause libraries

- Track adoption metrics and address usage gaps

- Capture and implement best practices

- Oversee system enhancements and upgrades

Advanced CLM Capabilities for Supply Chain Resilience

As organizations mature in their contract management journey, they can leverage advanced capabilities to further enhance supply chain resilience. Predictive analytics represents one of the most impactful advancements, enabling organizations to forecast potential performance issues before they materialize. By analyzing historical contract data and current performance metrics, predictive models can identify suppliers at risk of missing commitments, allowing proactive intervention.

Scenario planning tools embedded within modern CLM platforms enable procurement and supply chain teams to model the impact of potential disruptions. These capabilities let organizations test the effectiveness of contractual provisions under various scenarios, from natural disasters to geopolitical tensions. The insights gained from these exercises inform more resilient contract structures and contingency planning.

Compliance Tracking – Automated Solution for Varied Regulatory Requirements

Automated compliance tracking has become increasingly critical as organizations navigate complex regulatory landscapes across global markets. Advanced CLM solutions continuously scan both internal policies and external regulations, automatically flagging contracts that may require updates when requirements change. This capability is valuable for industries with stringent compliance mandates, such as pharmaceuticals, food, and defense.

Integrations

Real-time integration with supplier risk tracking platforms provides a dynamic view of changing risk profiles throughout the contract lifecycle. Rather than relying on point-in-time assessments during supplier onboarding, these integrations enable continuous evaluation against factors like financial stability, cybersecurity posture, and environmental compliance. When risk indicators change, the system can trigger reviews of related contracts and start mitigation measures.

Practical Implementation Tips from Supply Chain Contract Experts

Legal experts emphasize the importance of balancing standardization with flexibility in your contract management approach. While template-driven processes improve efficiency, rigid standardization can create friction when dealing with strategic suppliers with legitimate reasons for asking for changes. Successful implementations typically adopt a tiered approach, with strict standardization for low-value transactions and controlled flexibility for strategic relationships.

Integrated Contract Management

Procurement specialists recommend integrating contract management directly into sourcing processes rather than treating them as separate activities. This integration makes sure contractual terms reflect commercial negotiations and that performance metrics align with business requirements. Leading organizations have reconfigured their procurement workflows to initiate contract drafting earlier in the sourcing process, reducing cycle times and improving alignment.

Data Governance

IT leaders stress the importance of data governance frameworks when implementing CLM solutions. Establishing clear data standards, ownership roles, and quality controls prevents the “garbage in, garbage out” scenario that undermines many technology implementations. Particular attention should be paid to supplier data harmonization, ensuring consistent identification of vendors across systems to enable comprehensive analytics and reporting.

The Future of Supply Chain Contract Management

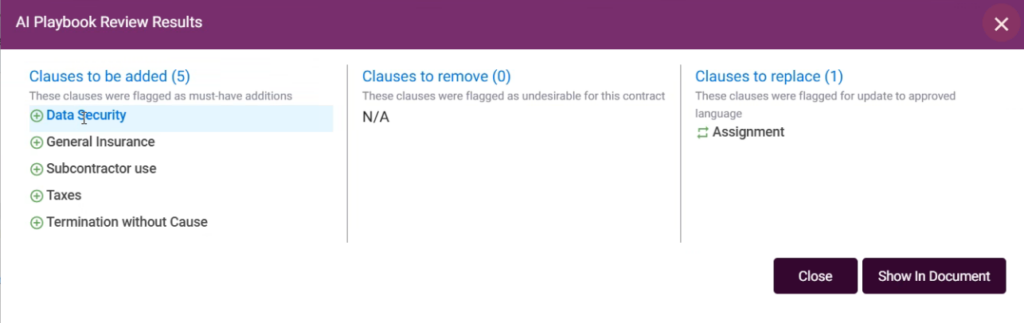

The next generation of supply chain contract management will be transformed by artificial intelligence and machine learning capabilities. Beyond basic metadata extraction, AI will increasingly analyze contractual language to identify potential risks, suggest ideal terms based on historical performance, and automatically draft clauses tailored to specific relationship requirements. These capabilities will shift legal and procurement resources from administrative tasks to strategic activities.

Distributed Ledger & Smart Contracts

Blockchain technology holds significant promise for supply chain contract transparency and automation. Distributed ledger architectures create immutable records of contractual agreements and later changes, reducing disputes about contract versions and amendments. Smart contracts—self-executing agreements with coded business logic—can automate payments based on verified performance milestones, improving cash flow predictability for suppliers while reducing administrative overhead.

Performance-Driven Models in Supply Chain Contract

We’re seeing a fundamental shift from traditional time-and-materials contracts toward outcome-based and performance-driven structures. These innovative models align supplier compensation with actual value delivered rather than inputs provided. For example, rather than buying maintenance services based on hourly rates, organizations are contracting for specific equipment availability levels, with incentives for exceeding targets and penalties for shortfalls. This evolution requires more sophisticated contract management capabilities to track performance and calculate variable compensation.

Sustainability & ESG

Sustainability and ESG considerations are rapidly becoming standard elements of supply chain contracts. Beyond basic compliance requirements, leading organizations are incorporating specific environmental targets, ethical labor practices, and governance standards into their agreements. CLM platforms must evolve to track these commitments and integrate with sustainability reporting frameworks to provide comprehensive knowledge of supplier performance against these emerging priorities.

Conclusion

Implementing effective supply chain contract management requires a strategic approach that extends well beyond technology deployment. Organizations that navigate this journey combine robust CLM platforms with thoughtful process design and comprehensive change management to transform how they create, execute, and manage supplier relationships.

The evolution of supply chain contracting from static documentation to dynamic strategic tools reflects the increasing complexity and uncertainty of global business environments. By establishing a strong CLM foundation today, organizations position themselves to adapt to emerging challenges while optimizing performance across their supply networks.

With Malbek’s Contract Lifecycle Management solution, organizations gain the technology foundation required for this transformation. The platform’s AI-powered capabilities, intuitive interface, and seamless integrations enable procurement and legal teams to collaborate effectively while maintaining control over complex supply chain relationships. As contract management continues to evolve from an administrative function to a strategic imperative, the right technology partner becomes increasingly critical for sustainable competitive advantage.